Busy dock doors are one of the highest-risk areas in a warehouse. You have forklifts moving in and out, trailers shifting at the dock, doors cycling all day, and limited visibility. Small problems here can quickly turn into injuries, product damage, or downtime.

This Dock Door Safety Checklist is designed to give your team a simple, repeatable way to spot issues early and keep loading areas safe and operational.

Why dock door safety matters

When a dock door fails, it rarely happens at a convenient time. Common results include:

- Forklifts forced to reroute around a blocked door

- Trailers waiting while a mechanic is called out

- Employees trying to “work around” damaged equipment

A basic checklist won’t replace full maintenance, but it will help your team catch problems before they become emergencies.

Before the shift – quick visual check

Have a supervisor or lead do a walk-through on active docks before loading begins:

- Clear path: No pallets, trash, or debris in front of doors or along travel paths.

- Lighting: Dock lights working and aimed where operators actually need them.

- Signage & markings: Safety signs and floor striping visible, not hidden behind pallets.

- Housekeeping: No oil, water, or loose cardboard on the dock floor or approach.

If any area looks unsafe, correct it before loading or unloading.

Door, leveler, and restraint checks

For each active door, have your team quickly review the equipment:

Door panels & tracks

- Panels are not bent, cracked, or missing sections.

- Tracks are free of obstructions and heavy damage.

- Rollers move smoothly with no grinding or binding.

Counterbalance / springs

- Door opens and closes without slamming or “free-falling”.

- Springs, cables, and hardware are intact, not frayed or broken.

Dock leveler or plate

- Deck raises and lowers smoothly.

- Lip extends fully and stores properly.

- No visible cracks in the deck, welds, or hinge areas. Safety legs and labels are in place.

Vehicle restraint / wheel chocks

- Automatic restraint engages the trailer properly and indicator lights function as intended, or

- Wheel chocks are present and used on every parked trailer at the door.

Any damaged component should be tagged out and reported — do not force equipment to operate if it is binding or out of alignment.

During loading and unloading

While the dock is active, keep an eye on:

Communication

- Operators understand the dock light system (red/green) or other signals being used.

- Only authorized personnel give the “OK to load” signal.

Trailer verification

- Trailer is parked, restrained or chocked, and landing gear down.

- No one enters a trailer until restraint/chocks are confirmed in place.

Operator behavior

- Operators do not ride the leveler or dock plates.

- Forklifts approach doors at controlled speed, horns used at blind spots.

- No one stands in pinch zones between the door, leveler, and trailer.

If anything looks off — trailer shifting, damaged restraint, unusual noises — stop work and verify before continuing.

Periodic maintenance items

Some items need more than a quick glance. These should be checked on a regular schedule by maintenance or a qualified service provider:

- Lubrication of rollers, hinges, and moving hardware

- Inspection of cables, springs, and pulleys

- Tightening of anchor bolts and structural fasteners

- Inspection of dock bumpers for excessive wear

- Testing of limit switches, interlocks, and safety devices

- Detailed inspection of welds, frames, and mounting hardware

If your team does not have the bandwidth or experience, this is a good section to hand off to a professional crew.

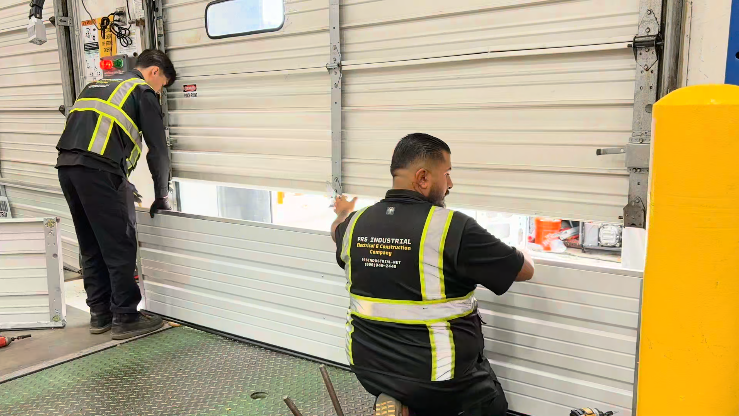

When to call PRS Industrial

Bring in PRS Industrial or another qualified contractor when you see:

- Doors that slam, bind, or will not stay in position

- Levelers that will not cycle correctly or show visible damage

- Repeated repairs on the same door or leveler

- Impact damage from forklifts or trailers

- Corrosion or structural damage around the dock opening or frame

A short service visit usually costs far less than one incident or a few hours of shutdown time.

Make it part of your routine

To get real value from this checklist:

- Train leads and operators on how to use it.

- Post a simple, one-page version at active docks.

- Include dock door checks in your normal PM schedule.

- Document issues and repairs so you can spot patterns and problem doors.

If you would like help tailoring this checklist to your facility, mention the Dock Door Safety Checklist when you contact us. Our team works in warehouses and industrial buildings across Southern California and can help you build a practical dock safety plan.

For more ideas on warehouse safety and maintenance, you can also review our Warehouse Solutions services or explore additional resources & guides.